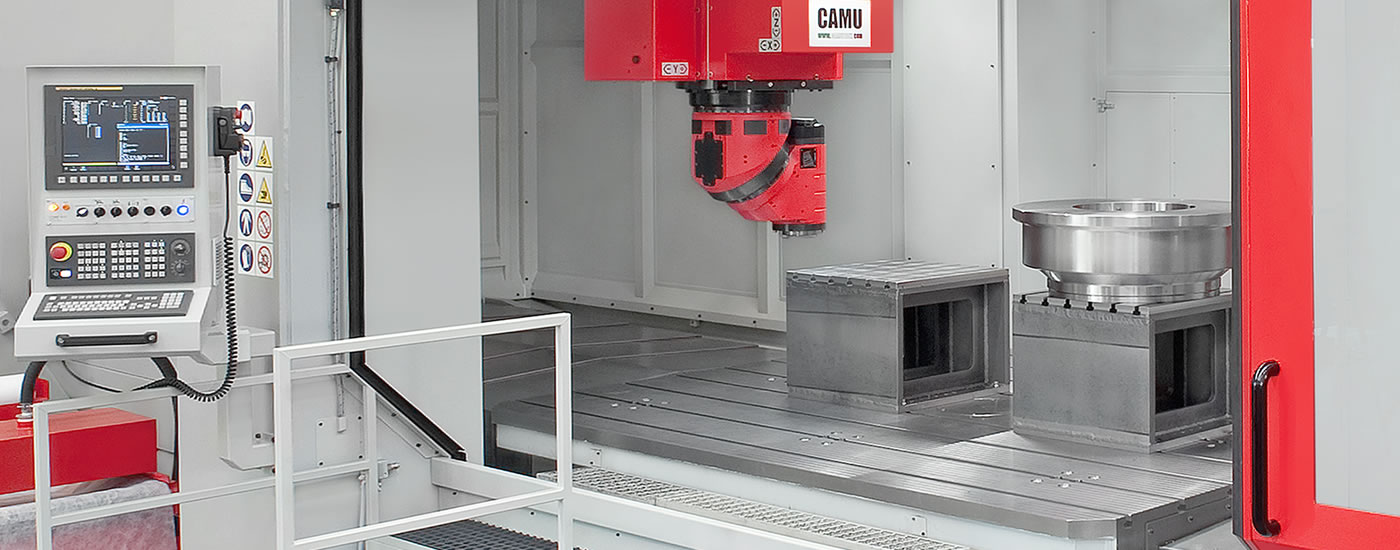

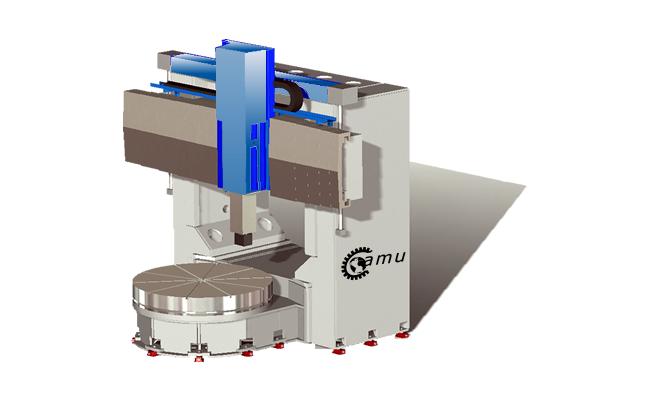

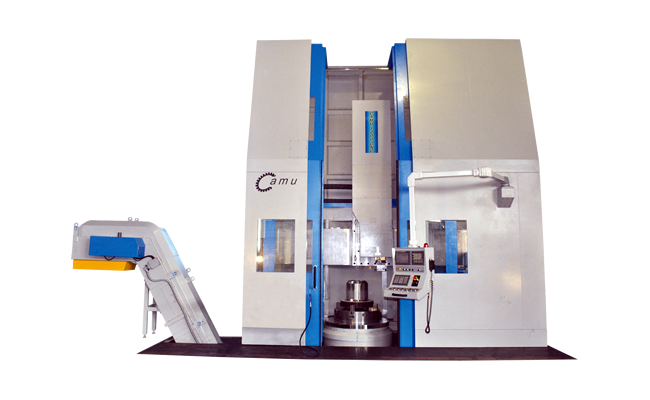

The machine is made entirely of electro-welded steel, designed using a 3D software and verified through FEM analysis. Basement, shoulders and fixed crossrail are constructed so as to provide maximum structural rigidity.

5-axis machine, ideal for those who need to work on castings, carpentry structures, large flanges and for the Petrochemical, Naval, Energy and general mechanical sectors. It is able to mill and drill on any type of material: alloy steels, copper alloys, stainless steel and titanium.

The standard numerical control is FAGOR 8065M, on demand is possible SIEMEN, FANUC or ECS.

CAMU is always available to design and manufacture machines of special size to meet customers’ needs.

TECHNICAL SPECIFICATIONS

| OPERATING DIMENSIONS: | 23/30 | 28/30 | U.M |

| Table size | 2300x3000 | 2800x3000 | mm |

| Distance between columns | 2700 | 3200 | mm |

| Distance between table and spindle nose | 1245 | mm | |

| Max. workpiece weight | >12000 | Kg | |

| Total machine weight | 30000 | 35000 | Kg |

| WORK AXES | |||

| Y-axis travel | 2700 | 3200 | mm | X-axis travel | 3700 | mm | Z-axis travel | 900 | mm |

| Rapid feed (Y e Z) | 20000 | mm/min | |

| Rapid feed (X) | 15000 | mm/min | |

| MILLING UNIT | |||

| Spindle motor power | 30 | kW | |

| Max. torque | 955 | Nm | |

| Speed range | 2 | Nr | |

| Maximum rotational speed | 4500/6000/8000 | rpm | |

| Spindle type | 50 | ISO | |

| Tool holder/td> | 69871 | DIN | |

| POWER SUPPLY | |||

| Voltage | 415 +/-10% | V | |

| Phase | 3 | Nr | |

| Frequency | 50 +/-5% | Hz | |